BirdSlide Installation Instructions

BirdSlide has been proven to be the most effective and cost-effective product application for ledges, eaves and angle irons. BirdSlide is a one-time fix for bird-free protection. It is lightweight, easy to cut, effortless to handle, and totally harmless to birds. It is important to understand that BirdSlide will evict all birds from their roosting and nesting areas when properly installed.

Step 1: Clean the site prior to installing BirdSlide

Cleaning the affected nesting or roosting areas is an important and necessary step for the proper installation of BirdSlide. Because BirdSlide is bonded to the affected surface; proper cleaning is necessary for maximum adhesion.

Over time, the buildup of bird droppings on a ledge, beam or eave can become quite a mess. All of the bird wasted and debris must be thoroughly and carefully removed. It is recommended that the bird feces and debris be first wetted and neutralized with a disinfectant. this will reduce the potential of breathing in hazardous aerosolized spores and will make your cleaning job easier. Use a disposable cloth to wipe the area clean. Sometimes, a hard nylon bristle brush will be necessary to remove droppings that are oxidized and have become hardened and encrusted into the surface. If there is a large build-up of bird feces, pressure washing may be necessary.

Note: It is important to always follow standard pest control safety procedures when cleaning and removing large amounts of bird waste. It is recommended that proper attire be worn which includes: a hazardous material suit (complete with hood and goggles), boots, gloves and a respirator. Some areas with a high content of bird feces will leave behind a stain even after you have manually cleaned or pressure washed the surface. This staining will not affect the adhesion process as long as the surface is clean and dry. Only those areas that will receive BirdSlide product will require manual cleaning or pressure washing (unless of course, you want to impress your customer). It is strongly recommended that you clean up your mess and properly dispose of all bird feces. You will have time to perform this task because the pressure washed area will need time to dry before you adhere the BirdSlide to your structure.

Important: All surface areas must be dry before attempting to install BirdSlide.

While you are waiting for the structure to dry, you can begin preparing the necessary tools and materials that you will need for the installation stage.

Tools for Installation BirdSlide does not require a lot of tools for installation. Simple cutting tools and adhesive is all you will need to begin installing. We recommend you have a hacksaw, tin snips, razor knife, tape measure, adhesive tubes and caulking gun, and a marking pencil. An option to consider would be to have a support technician cutting the BirdSlide beams to size with a portable table saw. This would enable the installation process to proceed more rapidly.

Step 2: Measure the length of the ledge for BirdSlide

Before you begin installation you will need to measure out the area that will need BirdSlide. BirdSlide is manufactured in 4-foot length beams that can be custom cut to fit the affected area. Measure out the surface area to be covered. Measure both width and the depth of the surface area to be treated. Measure and mark the BirdSlide beam and cut the size needed. Simple cutting tools like tin-snips, handsaws or a razor knife can be used to trim away excess area. A good job of measuring and trimming BirdSlide will insure a clean finished fit. And after color matching BirdSlide with a primer and exterior coat paint it will be virtually undetectable.

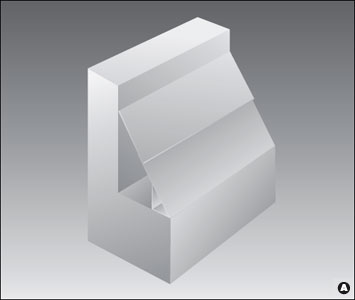

BirdSlide can be custom cut to fit most areas. The depth of the affected surface will determine how much of the slide trim area or “fin” will need to be trimmed away. If the depth is greater than 5-7/8″, BirdSlide’s Slide on Leg Extensions will be needed and are available from your local distributor. The extensions can be stacked and bonded together to create a longer slide that will cover the larger area (see diagram A).

BirdSlide on Leg Extensions will provide coverage for depths larger than 6 inches. For technical support call BirdSlide at 1-866-48 BIRDS for more information. Now that you have custom cut the BirdSlide beams for the measured area, it is time to prepare the beam for installation.

Step 3: Install BirdSlide

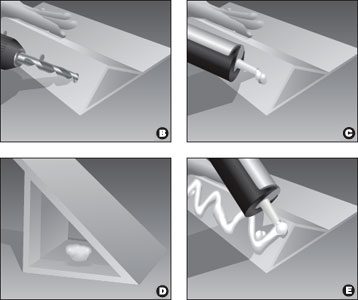

In the center of the bottom of the BirdSlide drill 1/2″ holes every 12 inches in a straight line lengthwise down the center. (See Diagram B). After you have drilled the holes, wipe away the plastic shavings and any electrostatic dust that might be clinging to the plastic beam. Using your caulking gun, apply the urethane based adhesive generously over the hole and on the bottom surface of the BirdSlide beam (See Diagram C). Enough adhesive should push through the hole to create a mushroom head on the inside triangle of BirdSlide (See Diagram D).

This will create a “bolt” or mushroom head effect that will enhance the adhesion process. In addition to the holes, lay down a generous amount of adhesive on the bottom of the BirdSlide beam with a zig-zag motion (back and forth).

Before you begin installing your trimmed BirdSlide beams, be sure that the surface area that has been cleaned in Step 1 is completely dry and free of dust.

Installing BirdSlide is very much like installing tiles or grout in your bathtub. You want to make sure that enough adhesive is laid down on the BirdSlide beam to secure a strong hold. This will insure a clean secure bond.

Tap the BirdSlide into place and wipe away any excess adhesive before it dries. The drying or curing of then adhesive bond will take up to 24 hours. However, within minutes BirdSlide will be attached strong enough for you to begin the last step: Painting.

Note: If needed BirdSlide can be installed upside down for Swallows or other wild bird protection, with urethane adhesive or screws. In addition seam connectors and end caps are also available to complete your installation. Call your local distributor or Ultimate Bird Control LLC at 866-48 BIRDS. When installing BirdSlide for swallows, wrap-around corners need to be miter cut. We advise these cuts be done by hand not a miter saw. All corners are different and there is no set angle to cut them. The best way is to cut them manually as you go.

When installing BirdSlide on ledges with a depth greater than 6″, leg extensions are necessary to cover these greater depths. Leg extensions come in 6″ x 4′ and are also available in custom sizes. Leg extensions can be double or triple stacked, glued, screwed, or riveted to BirdSlide in order to cover larger ledge depths.

BirdSlide Accessories

BirdSlide comes with a variety of accessories: seam connectors, slide on leg extensions as well end caps. End caps come in 3 different sizes: small, medium, and large. If your installation requires leg extensions, you will need a medium or large end cap to close off the ends of BirdSlide when BirdSlide is installed on open ledges. If your installation does not require leg extensions you can use the small end caps to cover the ends on an open ledge. End caps are designed to fit snug into the triangle part of BirdSlide. A dab of adhesive is all that is needed and it is secured. By using end caps you will prevent birds from hiding behind BirdSlide on open ledges.

“Think like a Bird”

Remember that in order to eliminate nuisance birds from a building you must think like a bird. Look for natural flat surfaces that occur on the structure that appear to be potential areas for roosting or nesting. The most desirable areas for nuisance birds to nest are often sheltered flat surfaces or areas that are somewhat protected by a stationary barrier (wall, I-beam etc) from wind currents and the outside elements. These areas must be eliminated. In consultation with your customer, use your best judgment as to the extent of the coverage area that will be needed.

Step 4: Paint BirdSlide to match the building surface

BirdSlide can be custom color matched to blend in with the structure you are working on. To achieve a quality result when painting BirdSlide, preparation is key. First, the BirdSlide beams should be wiped clean of any dust particles. Then, it is suggested that you paint the beams with a water based exterior coat primer to prevent premature paint chipping. This will also enhance the color and longevity of the paint. Many home improvement stores, paint stores and hardware stores will offer a wide selection of quality primers and exterior coat paints that will work well with BirdSlide. Another quick and easy painting alternative to consider is aerosol enamel spray paint. It works well with BirdSlide and comes in many colors but some colors can be limited. If an exact color match is not critical, cans of enamel spray paint can be an effective and suitable painting solution. Spray paints can also be found in the many locations already mentioned.

Remember to thoroughly coat the beam with the exterior paint. This will provide that clean finished look. Drying time will depend on the climate and the paint you are using. Be sure to review the information on the back of your paint can for drying time. Now that you have finished painting you have completed the final step of your installation. You and your customer can review a job well done and a bird control system that will immediately begin working to deter nuisance birds.

BirdSlide…The long lasting, easy-to-install bird control barrier that will provide you with years of “bird-free” protection.

Attention Bird Control Managers:

For large commercial jobs, BirdSlide can be pre-color matched in the manufacturing Process. Ask your authorized distributor for details.

WARNING: All surface areas must be thoroughly cleaned and pressure washed if necessary to remove all bird debris and droppings. It is important to exercise safety precautions when removing bird waste. Proper clothing and respirators are recommended. Consult your local licensed pest control company for further information. Do Not begin installing BirdSlide until all surface areas are dry. Areas that are not dry will not create a secure bond. Make sure to use urethane based adhesive for maximum bonding strength.